Updated 23 hours ago

Why More Industries Are Locking It In for the Long Term

JINBAO

Jinbao Paper operates a modern factory with strict quality control and exports thermal paper rolls to over 20 countries across Europe, Asia, and the Americas. The company supports OEM customization, fast delivery, and competitive pricing for global clients.

Jinbao Paper specializes in the production of thermal paper, copy paper, label stock, and other paper-based consumables. With 34 years of manufacturing experience and international certification, the company is committed to providing sustainable, high-quality solutions for printing needs worldwide.

This perspective avoids the overused claims like “fast printing” or “no ink required.”

Instead, it answers a more important question:

Why do businesses continue to choose thermal paper year after year?

This is a question that most of the current top-ranking Google pages fail to explain clearly or systematically.

What Are the Hidden Values of Thermal Paper?

In most introductions, thermal paper is simply described as “a type of paper that prints without ink.”

However, in real business environments, companies continue to rely on thermal paper not because it can print, but because it creates structural advantages within systems, workflows, and cost control.

These values rarely appear in product specifications, yet they determine whether thermal paper is adopted temporarily—or locked in long term.

Why Do Businesses Stick With Thermal Paper by Default?

1. Thermal Paper Is Part of the System, Not Just a Consumable

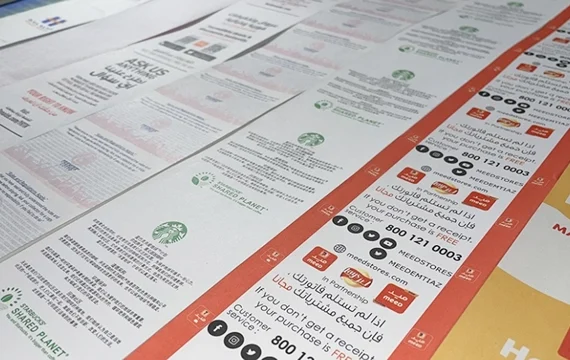

In retail, logistics, healthcare, and self-service terminals, thermal paper does not exist independently.

It functions as a fixed component within:

Printing hardware + software systems + operational workflows

Once a system is built around thermal printing, replacing it involves more than switching paper. It affects:

- Hardware compatibility

- Software configuration

- Staff operating habits

- Failure and downtime risk

This creates strong path dependency, making thermal paper the default long-term choice.

2. Thermal Paper Reduces Human-Related Uncertainty

Compared with inkjet or toner-based printing, thermal printing is far more predictable:

- No ink clogging

- No ribbon misalignment

- No manual color calibration

For chain stores, unmanned devices, and overnight operations, thermal paper acts as a risk-reduction tool, not just a printing material.

3. It Turns Printing Into a Background Action

In efficient operations, printing should never be a point of attention.

The real goal of thermal paper is simple:

It exists—but does not interrupt the workflow.

This is why it has become deeply embedded in checkout, sorting, and ticketing systems.

Where Do the Hidden Advantages of Thermal Paper Actually Show Up?

Advantage 1: Process Stability Matters More Than Single Print Quality

Many top-ranking articles emphasize print clarity.

For businesses, what matters more is:

- Stable output for 8–12 continuous hours

- No failures during peak periods

- Minimal human intervention

Thermal paper proves its value through long-term reliability, not one perfect print.

Advantage 2: Near-Zero Training Cost

Thermal printing requires almost no learning curve:

Load paper → Print → Done

In industries with high staff turnover—such as food service, retail, and warehousing—this is a heavily underestimated advantage.

Advantage 3: Extremely Scalable for Multi-Location Expansion

When a system expands from 10 locations to 100 or even 1,000, thermal paper offers:

- Strong standardization

- Low error rates

- Centralized purchasing and management

This scalability explains why chain businesses consistently favor thermal solutions

A Different Perspective: Thermal Paper Is Not a “Backup Option,” but the Optimal One

Many articles ask:

“Can thermal paper be replaced by other printing methods?”

A better question is:

In which scenarios is thermal paper already the optimal solution?

The answer is when these conditions exist simultaneously:

- High frequency

- Immediate output

- Automation

- No long-term archiving requirement

In such cases, thermal paper is not a compromise—it is the most efficient choice.

Why These Advantages Will Not Disappear Anytime Soon

1. Automation Equipment Will Only Increase

Self-checkout systems, smart lockers, and unattended terminals naturally favor low-maintenance printing solutions.

2. Businesses Focus on Total System Cost, Not Unit Price

The real value of thermal paper lies in reducing:

- Maintenance effort

- Labor involvement

- Operational risk

- Downtime losses

These costs often far exceed the price of the paper itself.

3. Materials and Environmental Technologies Are Evolving

New coatings and phenol-free solutions are addressing historical concerns, keeping thermal paper aligned with regulatory and sustainability trends.

Conclusion: What Is the Real Competitive Advantage of Thermal Paper?

If thermal paper is viewed only as “paper that can print,” its value is easy to underestimate.

From a systems, workflow, and risk-control perspective, its real strengths are:

- Lower operational complexity

- Higher process stability

- Easy scalability

- Alignment with information lifecycle

That is why, in many industries, thermal paper is not repeatedly “chosen”—

it is simply kept by default.

Written by

JINBAO

Jinbao Paper operates a modern factory with strict quality control and exports thermal paper rolls to over 20 countries across Europe, Asia, and the Americas. The company supports OEM customization, fast delivery, and competitive pricing for global clients.

Jinbao Paper specializes in the production of thermal paper, copy paper, label stock, and other paper-based consumables. With 34 years of manufacturing experience and international certification, the company is committed to providing sustainable, high-quality solutions for printing needs worldwide.

We'll Get Back Within 24 Hours